News

-

event

November 16-19, 2022

-

news

November 11, 2022

Impulse Operation Analysis Application Website (English.ver) Launched

How it Works

While efforts using AI and machine learning are often limited to proof of concept experiments, Impulse has been highly acclaimed for its operations worldwide. Today, Impulse operates approximately 21,000 model operations and still detects some anomalies. With this emphasis on practicality, our expertise in machine learning allows us to propose solutions to accelerate our clients’ businesses further.

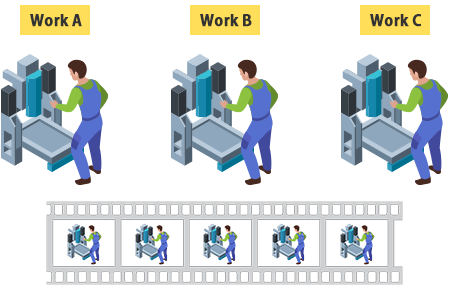

Impulse automates the monitoring of labor quality and analysis of performance by using machine learning video recognition technology for on-site work in various fields, including manufacturing sites. In addition to algorithms developed over many years of experience, Impulse completes the process of recording, training models, performing real-time detection, and visualizing results. No other software is needed.

Use Scenarios

-

Manufacturing / Production

Traceability- Automatic recording of work by certified camera/PLC.

- Recorded data searching.

-

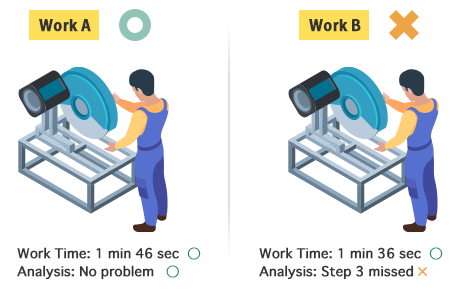

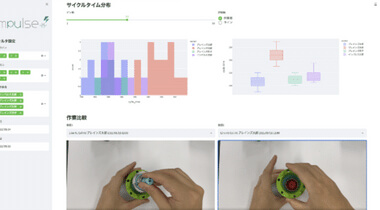

Worker Performance Analysis

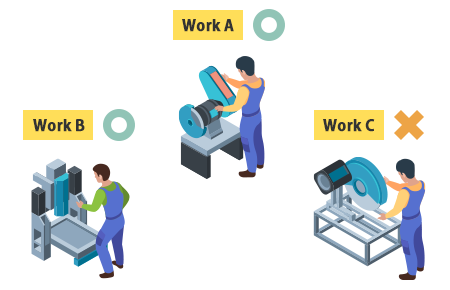

- Work process steps are automatically identified by our AI.

- The work time is aggregated by process and worker. Points for improvement are visualized.

-

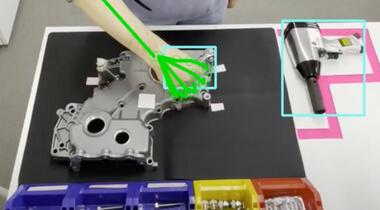

Real-Time Work Quality Monitoring

- Detecting missing work steps.

- Detecting work procedure errors.

We custom develop solutions for:

ROI-Generating Benefits

-

Performance Measurement Cost Reduction

Reduce manual stopwatch measurements and tabulation costs.

Benefit 1:

Labor ReductionEliminating 10 hours of labor per month over a 3-year period can

save up to $40,000!

-

Workshop Inspection Cost Reduction

Time required for inspection rounds by manufacturing and production site team leaders can be significantly reduced.

Benefit 2:

Supervision ReductionEliminating 2 hours per day spent on inspection rounds over three years can

save up to $150,000!

-

Cost Reduction through Production Process Optimization

Reduce cycle time by getting rid of the poka-yoke mechanism.

Benefit 3:

Process OptimizationThrough the application of work process optimization, a 1.0% efficiency improvement can result in savings of up to $100,000 over three years.

savings of up to $100,000over three years.

-

Production Quality Improvement. Assembly Defect Reduction.

By standardizing processes, work quality is stabilized, and manual assembly defects are reduced.

Benefit 4:

Reducing Human ErrorEven a slight reduction in the human-caused defect rate can significantly reduce the risk of warranties and recalls.

The benefits can be reflected in business performance in as little as one year.

Contact us for a free consultation with our experts.

Manual Assembly Challenges

-

No Progress in Improving Productivity

It’s hard to know what work processes have bottlenecks or are different from skilled workers. This prevents improving work efficiency and productivity.

-

Hard to Detect Human Errors

Product and service quality cannot be consistently guaranteed because work omissions and errors occur in the process.

-

Time-Consuming Work Analysis That Fails to Generate Solutions

Analyzing work processes and generating optimization measures is time-consuming and often doesn’t result in real solutions.

-

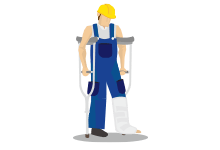

High Injury Risk from Heavy Workloads

We want to reduce the workload on workers and don’t know how. We want to reduce various risks in the work process and on-site.

1. Quickly Finding Bottlenecks

Impulse automatically records, aggregates, and compares the time each worker takes to complete an action with your most skilled workers to identify process bottlenecks.

2. Automatic Task Segmentation

With the “annotation function” of Impulse, AI automatically divides the work process. This function frees you from troublesome work.

3. Helps Improve Safety

Our AI detects safety and comfortability issues in all types of on-site work, such as movements, range of motion, posture, and load. It then visualizes various risks so that measures can be introduced to reduce workload and improve safety.

Main Features

-

1.

Automates Video Analysis

Machine learning models automate time analysis and work monitoring, freeing your team to focus on higher-value tasks.

-

2.

Enables Consistent & Continuous Evaluation

Removes human bias and idiosyncrasies from analysis, enabling consistent evaluation and continuous improvement.

-

3.

Comprehensive Dashboard

The dashboard allows you to view all statistics and visualize trends so that you can easily determine how to further optimize your operations.

-

4.

Work Quality Measurement

Impulse can also monitor work quality by applying its signature anomaly detection technology.

Why Choose Impulse?

-

Battle-Tested Algorithms

The accuracy of our algorithms has been refined through numerous real-world deployments in the most demanding conditions imaginable.

-

All-In-One Solution

Impulse is an all-in-one analysis solution, including recording, model training, inference, and dashboard. No other software or tools are required.

-

Comprehensive Support

Our engineers provide continuous support for tricky details like camera installation, accuracy tuning, and daily operation.

Contact us for a free consultation with our experts.

Typical Scenarios

We can help you optimally deploy Impulse according to your operating environment and challenges.

Below are the two most common scenarios.

1. Recording + Real-Time Analysis

The following are typical implementation scenarios for a system with automated recording and real-time analysis.

Note:

Typically, real-time analysis can be up and running within two months, depending on the work and the issues to be solved.

If you have existing cameras, it may be possible to use them to reduce total installation costs. Please get in touch with us for more information.

※Horizontal scrolling possible

-

1. Requirement assessment via video meeting or on-site visit.

(now)

-

2. Camera installation and recording system setup

(approx. 0.5 months)

-

3. Feasibility evaluation PoC.

(approx. 1 month)

-

4. Real-time analysis setup

(approx. 1.5 months)

-

5. Trial run

(approx. 2 months)

2. Offline Video Analysis

In this scenario, instead of building a system for recording and real-time evaluation, footage captured by an offline camera is analyzed.

Note:

Since no system integration is required, you can start using the Impulse work analysis application within 0.5 months.

If, after using this method, you decide to implement a real-time system, we will shift to scenario 1 above.

※Horizontal scrolling possible

-

1. Requirement assessment via video meeting or on-site visit.

(now)

-

2. Camera installation and recording system setup

-ヶ月

-

3. Feasibility evaluation PoC.

-ヶ月

-

4. Real-time analysis setup

-ヶ月

-

5. Trial run

(approx. 0.5 months)

FAQ

-

-

A.We recommend cameras from our camera partners and can loan you a test unit. We also support various other IP cameras and USB cameras, so if you already have cameras, please let us know.

-

-

-

A.The cameras should be installed so that (i) the worker to be monitored can be seen in the center of the camera, and (ii) their hands, tools, and workpieces are within its view. Our experts are available to help with any questions regarding camera installation.

-

-

-

A.Based on our experience, a resolution of about 1280 x 720 and 5 or more frames-per-second are usually sufficient. Please consult with us for further details.

-

-

-

A.Please consult with us, as it varies greatly depending on the speed and time resolution required for the work to be monitored.

-

-

-

A.Elemental tasks on the order of 0.1 to 1 second can be identified. It is not currently possible to identify operations in units smaller than 0.1 to 1 second.

-

-

-

A.It is possible to detect when work is forgotten, work is done in the wrong order, or work is done later/faster than usual.

-

If you have any other questions, please feel free to contact us.

Camera & Device Partners

The following camera providers support the Impulse operation analysis application.

Contact us for a free consultation with our experts.